Our fully equipped, cGMP and AIFA inspected facility covers an area of more than 155,000 sq. meters and enables API production from few grams to metric ton, even according to complex syntheses

- Multi-products and multi-purpose manufacturing lines

- Five independent production buildings

- More than 50 production lines

- Total reactor capacity: 560 m3

- Auxiliary equipment: 200 m3

- Intermediates and finished products: more than 2.500 metric tons on yearly basis

- Flow chemistry technology and high pressure hydrogenators (max. 60bar)

Our company’s mantra is to seek customer satisfaction, sustainable growth and continuous improvement.

To be efficient, the production of Active Pharmaceutical Ingredients cannot be separated from complex problem solving, in the scientific fields such as Organic Chemistry, Inorganic Chemistry, Physical and Analytical Chemistry, and Environmental Management. Read in these terms, it sounds like a difficult challenge to tackle, however, for PROCOS, the success of a production campaign is achieved through the highly skilled staff and the constant training of our personnel.

But this is not the only added value that PROCOS can bring forth in the production field; in fact, another of our strengths is our ability to scale-up processes from the laboratory to the industrial plant, always maintaining a constant relationship with quality, safety and efficiency. Moreover, we underline our great flexibility in switching from one process to another thanks to our multi-products and multi-purpose manufacturing lines.

To fully understand the complexity of our daily work, let’s imagine it as the preparation of a Formula 1 race. In this sense, the start of a production campaign is comparable to the set-up of a racing car that, in order to perform at its best, it must be ready in every single detail: starting from the chemical process, studied and optimized by a Team of Researchers and Technologists, to safety analysis and finally to the actual set-up of the manufacturing lines. Once done, the production campaign of an API begins and once it is finished and verified, we will obtain an Active Pharmaceutical Ingredients in compliance with our customers’ specifications.

For PROCOS and for us, working in API production means placing people at the center of our working day: We work to create all-around well-being both our customers and employees.

Paolo Muttini, Production Director & Claudio Comi, Plant Director

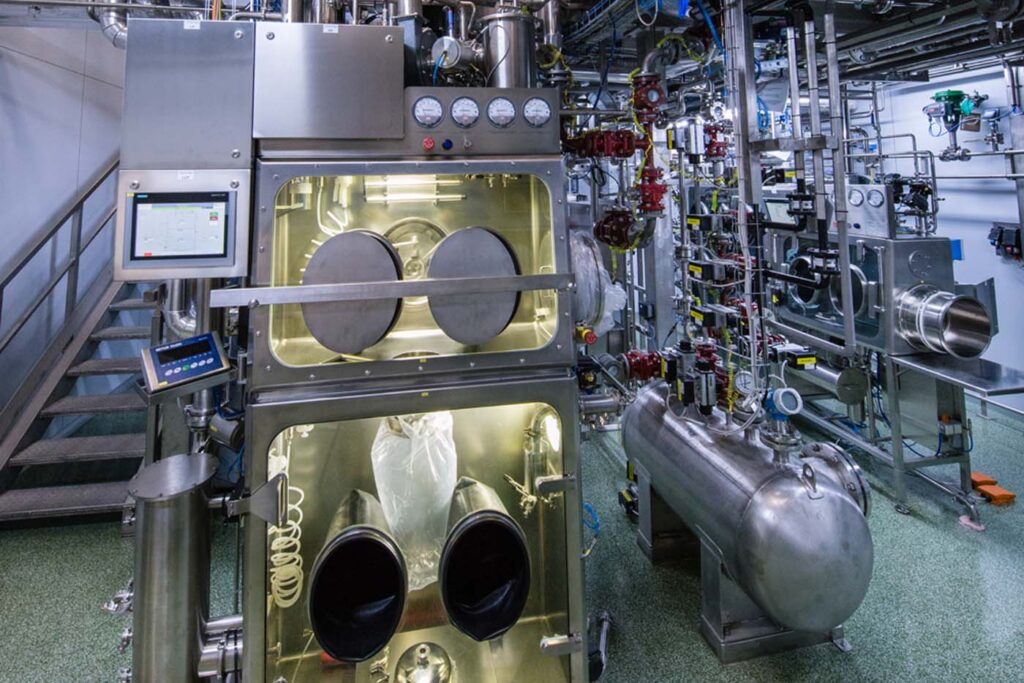

HPAPI UNIT

The HPAPI Unit has been a new and exciting challenge for PROCOS! In fact, from the very beginning, the company has moved to seek the cutting edge in the development and production of Highly Potent Active Pharmaceutical Ingredients, creating a workshop in the heart of the plant that is fully equipped with the highest quality Standards, in compliance with current GMP, to support our customers’ development programs from the initial stage to commercial supply.

PROCOS’ commitment is to contribute to one of the most important challenges of the present and the future, for small molecule, and to do it through knowledge and expertise to further service our partners in this important area of research.

The HPAPI Department has dedicated R&D and Quality Control laboratories, equipped with state-of-the-art equipment for the analytical development and release of these products; while the high containment operating units represent the cutting edge of HPAPI production, the same that allows PROCOS to address its projects within the oncology sector as well.